What are the 5 most common mistakes related to the installation, operation, and maintenance of AODD pumps?

Posted by CDI Products on Jul 26, 2022

Air-operated double-diaphragm (AODD) pumps are employed in an extensive number of industrial applications and across a variety of industries including petrochemical, pharmaceutical, water management, semiconductor, oil and gas, painting and coating, and beyond. AODD pumps are typically utilized in transfer applications and can handle a broad variety of materials, including sludges, slurries, abrasive, and shear-sensitive fluids. Their one-of-a-kind shape makes them excellent for transporting highly abrasive or viscous materials. While they are rugged, dependable, and simple to maintain, they may be loud, prone to icing, and are best suited for low pressure applications.

How does an AODD pump work?

An AODD pump is a positive displacement pump that is powered by compressed air. The compressed air is transferred between chambers through a connected shaft that enables the chambers to move in unison. This back-and-forth action pulls liquid out of one chamber and into the discharge pipe while simultaneously filling the other chamber with liquid. AODD pumps can achieve flow rates of up to 280 gallons per minute (gpm) (1,060 lpm). This gives the pumps an edge over other pump technologies, in which it may be difficult or even impossible to have that much control over the flow rate. The flow rate can be obtained by simply increasing the air pressure or the discharge head.

What are the unique qualities of an AODD pump?

Due to the absence of internal seals and moving components that require lubrication and cooling, an AODD pump can operate dry indefinitely without causing damage. A clean compressed air supply is required for operation, and pumps can only pump fluids at pressures equal to or lower than that of the available air supply. Because they are powered by compressed air rather than electricity, the simple design of an AODD pumps makes them easy to operate, and cost-effective to repair. Although AODD pumps are often regarded as the workhorses of the pump work, there are several factors that can impede the efficiency and operational life of an AODD pump.

Five most common mistakes related to the installation, operation, and maintenance of AODD pumps

- Using components that aren't abrasion resistant

When selecting an AODD pump for a certain application, some pump components can make a significant difference in overall performance and the mean time between failure (MTBF). When pumping abrasive fluids, it is important to consider using components that are designed using material resistant to abrasion. Manufacturers often replace traditional rubber valve seats with ones made with more abrasion resistant high-performance polymers in order to lessen the wear associated with abrasive applications. - Pumping a substance that isn't chemically compatible with the pump's components

Before selecting an AODD pump, it is important to have a solid grasp of the chemical properties. It is essential to be certain that the fluids being transferred are chemically compatible with the materials used to manufacture the pump. This comprises elastomers, castings, and potentially hardware in the event that the pump is going to be submerged. Because safety is a main concern with many different chemicals, it is crucial to select a pump made from materials that are compatible with the chemical that is being moved through the system. - Considering Operating Temperature

Another important factor that is often overlooked is the operating temperature. Even though AODD pumps can handle fluids as hot as 220 degrees Fahrenheit (104 degrees Celsius), temperature limits their building materials. Some materials degrade, crack, swell, or disintegrate at high temperatures, reducing corrosion resistance and causing early failure. Lower temperatures reduce diaphragm flexibility. Each diaphragm has a temperature range. Maximum flex life (the diaphragm's predicted lifespan before replacement) can't be expected if the pump is used at severe temperatures. Internal pump components may be qualified for low or high temperatures, but it doesn't mean the pump body material is, and vice versa. When configuring an AODD pump, check all components' temperature ratings. AODD pump manufacturers publish the temperature limits of their materials. - Lack of consideration for compressed air supply

The quality and pressure of the air may affect the life of an AODD pump more than anything else. After all, compressed air is how they get their power. Just like dirty air can affect how well a pump works, air pressure can make the difference between a pump that works at full capacity and one that doesn't work at all or doesn't work well. How fast an AODD pump works and how much flow it makes are both controlled by the air pressure. If the pump is getting more pressure than it needs, it will cycle quickly, which leads to inefficient operation, more wear on the pump, and failure before it should. Air filters or air regulators guarantee the air is clean and at the right pressure. The fluid must have sufficient time to enter and exit each fluid chamber, and the valve balls must sit appropriately. This will ensure that each stroke is completed, hence enhancing the performance of the pump. - Pump fittings that are not sized correctly

Matching flow and pressure ratings to the flow and pressure requirements of a process is an important part of pump sizing. Ensure that the fluid inlet and output piping/fittings are at least as large as the pump's connection size before fluid begins to flow through the pump. Doing so during installation will increase the efficiency of the pump. In simple terms, this means for a 2-inch pump installation, connecting it to 2-inch or larger plumbing is the best option. If the pipe is smaller than the pump, fluid suction will be restricted, affecting pump flow, efficiency, and diaphragm life negatively. Proper sizing is critical for pump longevity and optimal performance.

With these five factors under consideration, AODD pump users may achieve the highest overall pump output efficiency. In order to produce successful output, it is necessary to ensure smooth operations and a regular schedule while minimizing downtime to maximize productivity.

How CDI Can Help with AODD Pumps

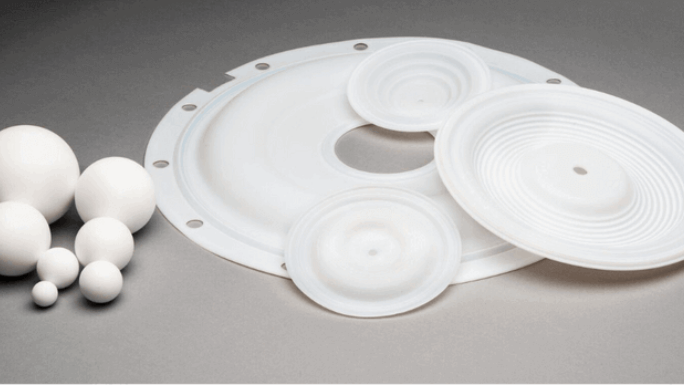

AODD pumps need quality components to handle sludges, slurries, abrasive, and shear-sensitive fluids. Whether you are looking for Diaphragms, Balls, Ball Seats, O-Rings, Piston Assemblies, Body Components, or Custom Molded Products, we have the materials portfolio, custom engineering and design, and manufacturing capabilities to meet the most challenging applications.

Topic: fluid handling, High-Performance Polymers, vertical integration in polymer manufacturing, AODD Pumps