Leading Innovations in Aerospace Sealing Technology and Systems

Performance and Endurance with High-Quality Polymer-Based Sealing Solutions

At CDI Products, we address key challenges within the aerospace industry with our innovative product offerings. As a high-performance polymer manufacturer, we deliver advanced sealing technology that provides exceptional solutions for the next wave of efficient aircraft. Our solutions facilitate energy transfer, maintain fluid integrity, and exclude contaminants, ensuring our components endure without wear.

Our Aerospace and Defense sealing systems are engineered to survive the demanding conditions of the most severe environments, embodying the essence of mission-critical performance solutions. With our expertise in elastomer, thermoplastic, and thermoplastic composite materials, we've positioned ourselves as leaders in delivering high-performance solutions for Aerospace and Defense.

Aerospace Components and Systems

Innovation and Excellence in Aerospace products & Design

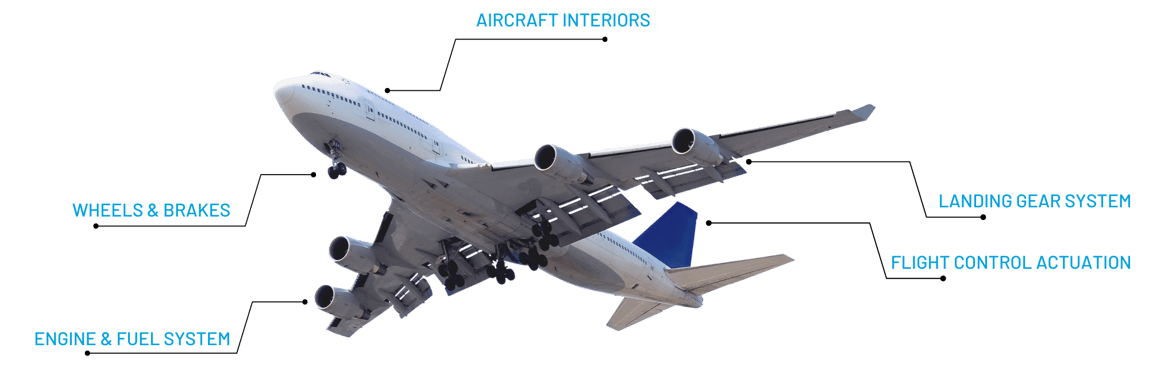

At CDI, we are committed to providing excellence for today's Aerospace and Defense industry. Our expertise lies in designing and developing innovative solutions for many systems, including landing gear systems, flight control systems, engine & fuel systems, hydraulic utility systems, wheels & brakes, fuel systems, and beyond. We believe in ensuring aerospace applications are supported with superior sealing solutions. Our products and components span from Static Face Seals, T-Seals, Piston Rings, OptiSeal®, Cap Seals, OptiSeal® Face Seals, and Backup Rings to Bearings and Scrapers. Check out our Online Digital Aerospace Catalogue.

The highly critical nature of components and products for aerospace and defense applications means manufacturing of those products must meet the highest level of safety, quality, and reliability. With vertically integrated manufacturing, CDI provides far more than mere part production. With over 30 polymer manufacturing processes, our team of skilled machinists, operators, and technicians uses cutting-edge processes and technology to manufacture the highest quality seals, wear products, and functional components for the aerospace industry.

Backed by extensive research, testing, and manufacturing capabilities, our design and development team often work together with our customers to design performance polymer products which meet the unique application specs and environmental conditions. In the aerospace and defense market, some of the most used manufacturing processes include injection molding, extrusion, ram and melt molding, compression molding, precision CNC machining, large diameter machining, turning and milling, and billet production.

CDI is proud to meet the stringent standards for AS9100 certification. The AS9100 certification is an internationally recognized quality management system standard specifically designed for the Aviation, Space, and Defense industry. It offers a comprehensive framework for manufacturing suppliers, ensuring they can consistently provide products that meet customer and regulatory requirements while prioritizing safety and reliability. CDI’s North America manufacturing facility has received certification to the AS9100D quality management standard through Lloyd’s Register. AS9100 is the international quality management system standard for the Aviation, Space, and Defense industry. AS9100 provides manufacturing suppliers with a comprehensive quality system for providing safe and reliable products. The certification program is managed by the International Aerospace Quality Group (IAQG). CDI is an active participant and contributor to the SAE Organization - Aerospace which oversees the development and revision of numerous standards used in the aerospace industry.

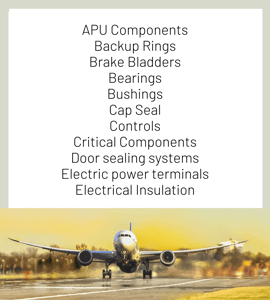

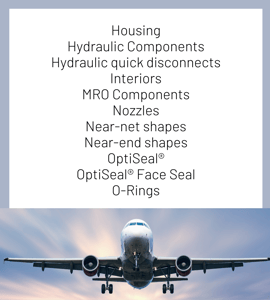

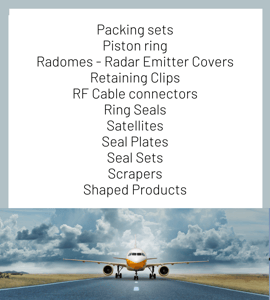

Here is a sample of the many products manufactured using high-performance polymer products for the aviation, space, and defense industry:

The aerospace and defense industry has strict requirements and challenging specifications all driven to ensure optimal efficiency, safety, and environmental compliance. To work with the leaders of this industry, polymer product manufacturers must deliver the best quality materials and compounds. Those materials must provide the significant weight savings, insulation, tribological efficiencies, emissivity, and reliability aerospace and defense companies demand.

With advanced material science and an extensive material portfolio, CDI leverages the strength, chemical resistance, extreme temperature tolerance, and sustainability of polymers. Advanced polymers can withstand the extreme temperatures found at high altitudes and offer a non-corrosive base with low water absorption allowing for natural buoyancy.

Polymers are often the go-to material portfolio for aerospace as the materials can offer the low friction, high strength, and temperature stability (solar load) essential for flight and air travel.

Challenges in the Aerospace and Defense Industries

Balancing Efficiency and Safety in High-Stress Environments

Whether they be commercial or military grade, aircraft are subject to extreme fluctuations in altitude, pressure, temperature, and speed, coupled with dynamic weather and environmental conditions. To mitigate risk, aircraft are designed to withstand an incredible amount of stress and strain, and aircraft manufacturers incorporate a substantial safety margin into their designs.

Manufacturers across the aerospace industry are unified in their goal of optimal strength-to-weight ratios – as the lighter the aircraft, the more fuel efficient. For this reason, thermoplastics and other polymer materials have made a tremendously positive impact in the global industry.

Beyond weight reduction, polymers also deliver strong value in a variety of applications due to their unique characteristics. Polymers also often outperform metallic components in terms of corrosion and fatigue resistance, insulative properties, solar load, and durability. When lives are on the line and environmental conditions cannot be controlled, every piece of equipment and every component on an aircraft must be carefully considered. In essence, each element is mission-critical, and choosing the best materials can prevent failure.

Developing cutting-edge technology presents unique obstacles that demand innovative solutions within the realm of challenges in the aerospace and defense industries. At CDI, we work with both industries to closely to tackle these challenges and extend the boundaries of our capabilities in high-performance sealing and components.