How Cobots Are Powering Smart Manufacturing

Posted by CDI Products on Jul 23, 2021

Innovations such as smart manufacturing, the Internet of Things (IoT), and artificial intelligence (AI) are revolutionizing traditional manufacturing.

The rise of collaborative robots, or “cobots,” is one powerful example of the way smart technology empowers businesses to improve everything from production efficiency and capacity to employee safety and satisfaction.

Here’s an overview of the background and benefits of leveraging cobots within manufacturing teams.

Cobots and Augmented Intelligence

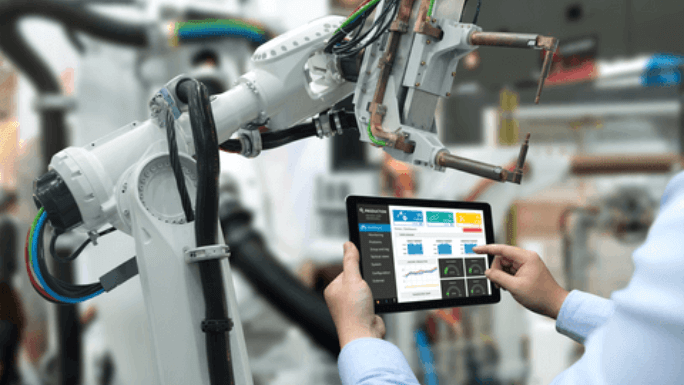

Cobots are designed to operate in conjunction with humans to perform their tasks. They provide safe, versatile, and easy-to-use automation that actively helps manufacturing teams in their day-to-day work. Crucially, a collaborative approach does not displace human workers – cobots work alongside them to drive efficiency, safety, and better working conditions.

One reason collaborative AI solutions like cobots work so well is that humans and machines have different strengths. Whereas machines excel in quickly and accurately completing rote, repeatable tasks, humans have a more nuanced ability to make quick judgements, adapt effectively, and think strategically.

When humans and machines work together, they can achieve what the authors of a recent article in the Harvard Business Review call augmented intelligence – a combination of machines’ artificial intelligence and humans’ authentic intelligence.

According to the authors, this tandem approach is the future of intelligent work, allowing organizations to be more efficient and accurate while enhancing creativity. In fact, the productive coexistence of human and machine workers will give rise to what the authors call “the new diversity” in the workplace.

Here’s some more in-depth info on the main advantages of cobots.

Safety and Satisfaction

As people-focused machines, cobots are designed to simplify and streamline the tasks workers perform. Cobots are especially valuable in handling tasks that are too tiring, unpleasant, monotonous, or dangerous for people to carry out. Most cobots feature sensors to ensure they never use incorrect force or collide with people or objects.

Reducing repetitive tasks and safety risks not only improves employee satisfaction and performance, it can also save time and money by reducing disruptions related to accidents or employee turnover.

Efficiency and Consistency

Certain tasks can be streamlined and optimized when completed by machine. Unlike humans, cobots can be programmed to do certain tasks to a specific degree of accuracy and at an exact speed, which makes them consistent and predictable. This helps with forecasting and production planning, reducing waste, lowering costs, and giving teams more time to focus and innovate.

Also, cobots leverage reporting functionality to supply seamless data on machine maintenance, potential bottlenecks, and other inefficiencies, further helping to improve quality and productivity.

Enhanced Flexibility

Cobots can be quickly programmed to carry out a variety of tasks, making them a more flexible solution for certain applications. This adaptability means cobots can be especially valuable for businesses that must produce a high variety of quality products at a wide-ranging production volume.

Cobots are also easy to assemble, disassemble, and relocate. Plus, cobots can be leveraged periodically or temporarily allocated to multiple tasks throughout a work week, without any loss in efficiency.

Improved Quality

Smart manufacturing tools can automatically generate precise data around cobot performance. By allowing managers to more efficiently measure and monitor key performance indicators (KPIs), cobots contribute to improved product quality.

Cobots also have sensors and smart systems that link up to the Industrial Internet of Things (IIoT) and task-specific systems, such as warehouse management, freeing up people for more sophisticated, productive roles.

Predictive Maintenance

While maintaining equipment can be a time-consuming task, cobots make this a lighter lift through predictive maintenance functions. Many of these machines can be programmed to run automatic systems checks and can accurately diagnose potential issues.

This means that smart factory managers will receive alerts and can resolve maintenance issues before they cause operational downtime, further improving the quality and efficiency of production efforts.

With automation, digitalization, and robotization transforming processes, manufacturing will continue to evolve. Leveraging the combined power of humans and machines, cobots offer manufacturers the benefits of augmented intelligence throughout their operations, resulting in better quality products and safer, more productive workplaces.

Topic: Cobots, artificial intelligence in manufacturing processes, augmented intelligence