Is Injection Molding the Right Choice for Your Polymer Project?

Posted by CDI Products on Jun 22, 2021

OEMs across industries have many options for producing plastic components built to handle critical challenges. However, the benefits and best use cases among them vary considerably.

In the injection molding process, machines inject molten polymer materials under high pressures and speeds into closed molds, resulting in high volumes of identical components that meet rigorous mechanical requirements.

Alternatives to injection molding include extrusion, blow molding, thermoforming, machining, and 3D printing – each with its own advantages. But if the project calls for precise capabilities, few processes deliver the quality and efficiency of injection molding.

In this blog post, we examine nine key characteristics of injection molding for complex polymer components. We also take a closer look at which projects are best suited for injection molding.

9 Characteristics of Injection Molding for Complex Polymer Components

Injection molding is remarkably versatile, and OEMs often gain efficiencies as well as cost savings over other plastic manufacturing processes. For OEMs with complex design requirements and no room for error, injection molding provides several advantages.

- Precision and Strength — One of the hallmarks of injection molding is its ability to repeatedly create precision parts. State-of-the-art presses are capable of holding tolerances to +/-.001 inches in materials with high shrink rates. Using fillers added to natural resins, component properties can be further enhanced. For example, glass and carbon fiber can be added to increase strength and stiffness, lubricants such as PTFE can be added to reduce friction, and additives can increase UV resistance or provide antimicrobial properties to the finished product.

- Design Flexibility — Injection molding allows engineers and design teams to create components with complex geometry and shapes. Plastic’s high-injection capabilities help engineers to design uniform thinner-walled parts, replacing more costly (and heavier) thicker-walled die-cast metal parts. Plus, modern injection molding presses are capable of producing a wide range of part sizes with significant high and low variances for tonnage and shot capacity. Injection molding parts also offers a considerable benefit over machining because it can produce complex shapes at a much lower cost.

- Range of Material Types — From PEEK to fluoropolymers and other thermoplastics, a large selection of engineering-grade plastic can be used to produce injection-molded parts and components. Plus, injection molding allows for multiple polymer materials and/or inserts to be joined into a unified body. It’s worth noting that injection molding isn’t just for plastics. Elastomer materials, also known as high-consistency rubber (HCR), also can be used. This flexibility allows OEMs to find exactly the right material (or mix of materials) for their application and operating environment.

- Consistency and Quality Control — Injection molding is a repeatable process that allows OEMs to achieve predictable product reliability at high volumes. A manufacturer with in-depth knowledge of material science and parts engineering can design for pressure, temperature, polymer choice, and other variables that influence a part’s quality and manufacturability. Using the right design technology, manufacturers can design injection molds to optimize mold design, processing parameters, and part quality prior to mold construction.

- Scalability — While injection molding has low-volume capabilities, high-volume production in the millions is often the most cost-effective use.

- Finishes and Color — Injection molding allows for a wide range of molded-in colors and finishes that can withstand harsh environments without the additional cost (or environmental impact) of a secondary painting operation. Additives include weather resistance, heat stability, UV protection, antimicrobial, lubricity, anti-static, and flame retardants. Finishes, such as textures, and colors can be for cosmetics, safety alerts, transparency to opaqueness, or light diffusion.

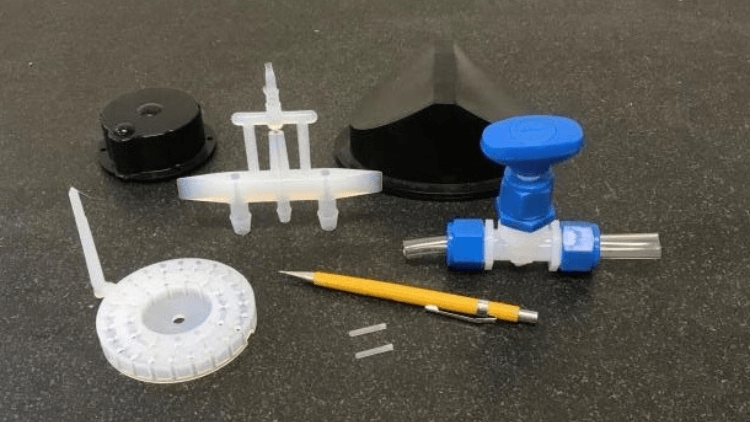

- Combine Multiple Materials — Complex part designs sometimes require components made of different materials. Injection molding allows you to combine different materials to increase strength, reduce costs, and get the best product performance. Materials that can be molded together include threaded inserts, metals, elastomers, and other plastics — for example, a semiconductor seal employs an elastomer bonded to PEEK. The image below provides a glimpse into a range of injection molding capabilities across industries.

- Faster Production Timelines — Vertically integrated manufacturers with robust on-site capabilities can design for manufacturability before the injection molding process starts, minimizing the need for expensive tooling changes. Additionally, with an AI-enabled injection molding machine, operators are alerted about issues before they occur. This results in more effective maintenance, fewer repairs, and less downtime for both the machine and the mold. These efficiencies shorten product development timelines, reduce costs, and get high-performance components to market faster.

- More Sustainable — Compared to traditional manufacturing processes, injection molding produces low scrap rates. That’s because injection molding uses a higher percentage of the raw material, resulting in less waste. Plus, manufacturers that have invested in energy-efficient injection molding machines eliminate the need for oil and its disposal.

How to Determine If Injection Molding Is Right for Your Next Project

Across industries and critical environments – from industrial and aerospace to automotive and medical – injection molding is a proven go-to solution. However, not all projects benefit from injection molding efficiencies. Projects that are ideal for injection molding typically involve:

- Large volume productions

- Complex component designs and shapes

- Complex applications requiring precision, tight tolerances, and/or part consistency

- Applications in which the surface finish is a factor

4 Questions to Ask Your Manufacturing Partner About Injection Molding

A manufacturing partner with expertise across all phases of the process – from materials selection to part design and testing through to manufacturing – is essential to a successful outcome. When considering a partner, ask these questions:

- How will the material influence my product performance?

- How will a mold flow analysis benefit my project?

- What secondary operations are available (such as lathe, mill, kitting, and assembly)?

- Can I use injection molding for my billet project?

Plastic injection molding offers diverse capabilities for a wide range of industries. In addition, advances in technology will continue to help manufacturers optimize the quality, sustainability, and adaptability of injection-molded parts.

Topic: polymer manufacturing, injection molding, polymer components