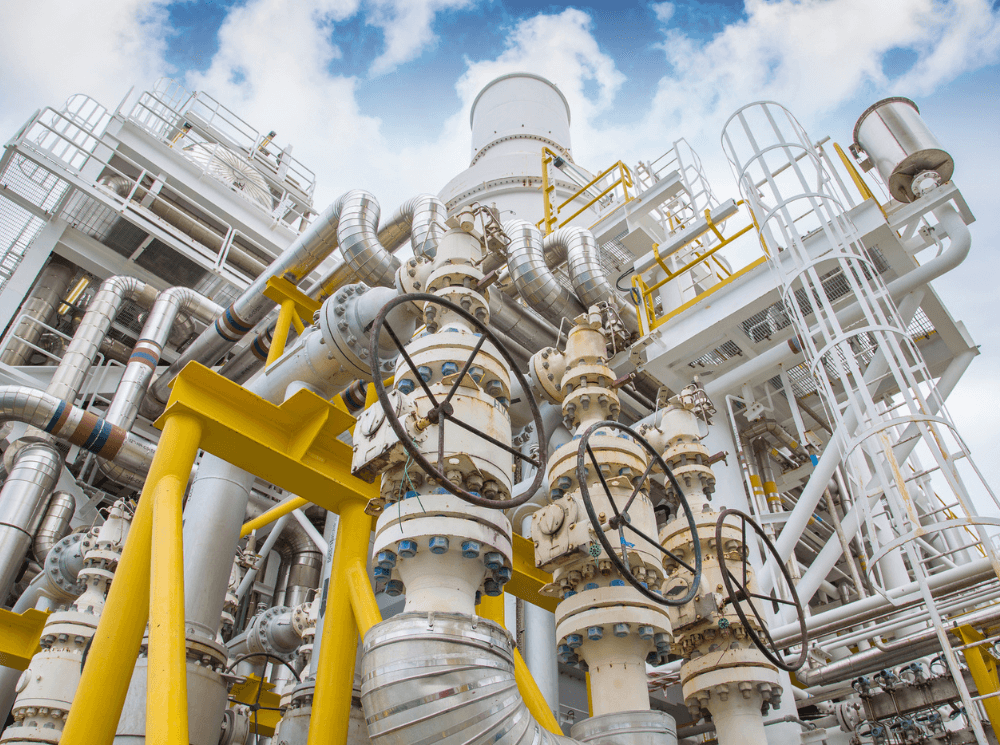

When a potentially catastrophic issue with a boiler feed pump in a Texas Chemical Plant arose, one of our customers, a pump repair service provider, contacted us to find a solution. The chemical plant in question is a producer of products that are crucial ingredients - like Amines, Ethanolamines, and Propylene Glycol - vital to a number of global industries such as electronics, cosmetics, energy production, and construction. Failure at the chemical plant could not only result in a costly plant shutdown causing potential shortages of chemicals required by these critical markets, but it might also put people at risk, raise health and safety concerns, and cause environmental issues.

Read the case study to learn how we helped find a solution that mitigated lost time and reduced repair costs.