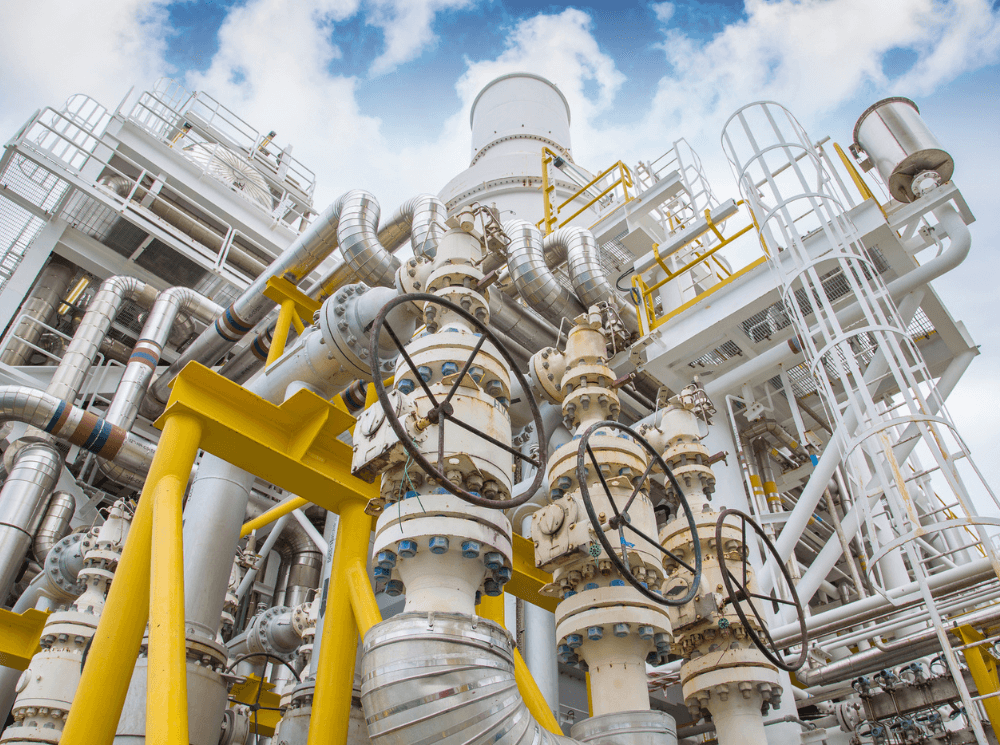

A chemical facility in Texas was experiencing significant problems with leaking packing rings on three of their major reciprocating compressor units. The packing failures led to frequent replacement on the packing rings as the products were lasting as little as a few months on all three compressors. The resulting operational interruptions were costing time and money, but also the unreliable packing rings were becoming a continuous concern.

Read the case study to learn how we helped solve this major challenge.