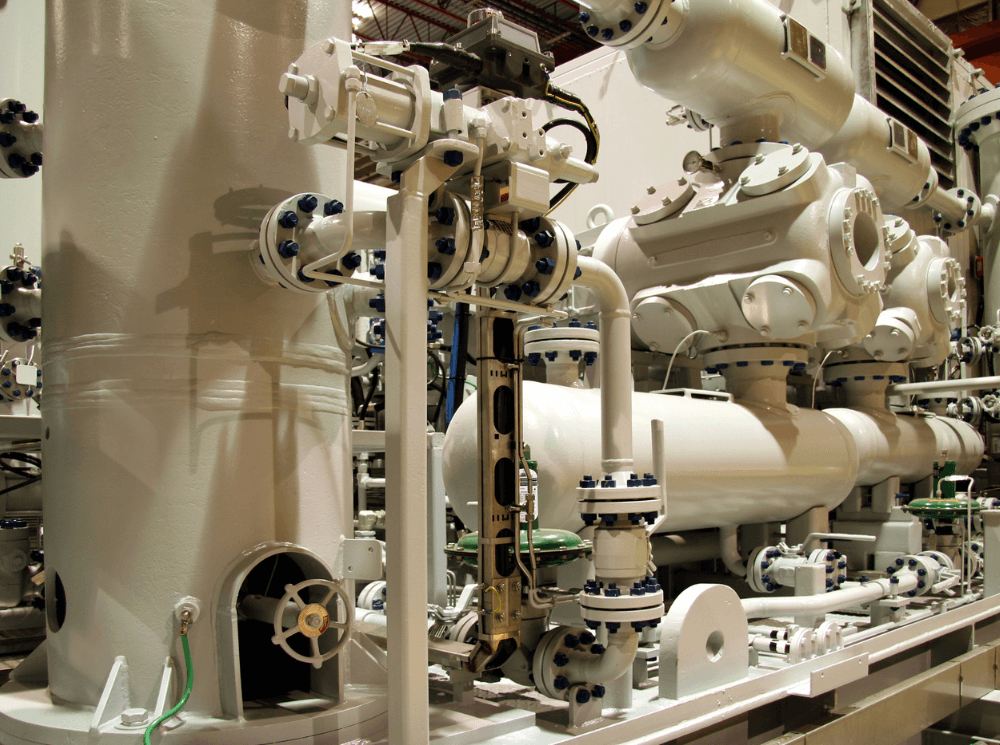

Circulating pumps at a nuclear facility are critical to safety and must perform with minimal downtime. A nuclear power plant on the East coast was experiencing significant problems with their bushings in a seawater circulating pump. These bushings were lasting well below accepted maintenance intervals. The resulting service interruptions not only cost time and money, but the unreliable bushings were becoming a serious safety concern.

Read the case study to learn more about CDI's custom bearings resulting in doubling MTBR.